4 or more dosing conveyors ensures stable grading curve that meets most demanding EU directives.

With the support of RFID card, the driver of a dumper truck can handle the entire loading process by himself with a single press of the button.

MP400 helps to increase use of recycled materials inside your organization.

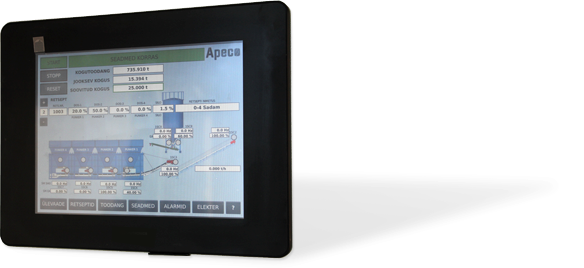

This modern equipment for mixing aggregate makes it possible to produce various aggregate mixes more flexible and helps to meet the ever-increasing quality requirements. The equipment is designed to produce various long fractions or graded aggregate at a rate of 400 t/h according to the grading curve required. High flexibility and an automated process boost productivity and efficiency across the entire production process. Modern automated system allows all of production to be monitored ensuring a high-quality final product.

Features and benefits

Increases

All drawing dimensions are approximate and in millimeters. Apeco Group reserves the right to alter the specification of the machine without any notice.

Thanks to its innovative solutions, all of the equipment is very easy to control and handle. Based on a previously stored recipe and with the support of a RFID card, the driver of a dumper truck can handle the entire loading process by himself with a single press of the button, which will activate the entire mixing line. With the equipment, the necessary quantity of material can be metered into the load bin of a dumper truck according to the order.

Features and benefits

All drawing dimensions are approximate and in millimeters. Apeco Group reserves the right to alter the specification of the machine without any notice.

| Data | |

| Production rate | Max. 400 tph |

| Power | 18 kW |

| Bin capacity | 16 m3 |

| Conveyor frames | Galvanized |

| Main frame | Painted |

| Operating measures | |

| Working width | 3150 mm |

| Working length | 19 490 mm |

| Working height | 4190 mm |

| Transport measures | |

| Transport width | 2550 mm |

| Transport length | 19 490mm |

| Transport height | 2880 mm |

| Weigth | 26 700 kg |

All drawing dimensions are approximate and in millimeters. Apeco Group reserves the right to alter the specification of the machine without any notice.

All drawing dimensions are approximate and in millimeters. Apeco Group reserves the right to alter the specification of the machine without any notice.

"Download .pdf"

Product sheet

“The mixing unit is not something new to the world - however in collaboration with Apeco a bespoke suit has been created for our company. It design is tailored for our materials (both the aggregate and the binders produced). Our company's hope is that this equipment will take us to the next level in the production of aggregates.”

Riho Iskül - Development Director